Chrome repair and restoration require a meticulous approach due to its sensitive nature. Protecting against scratches, stains, and corrosion demands sterility and minimizing external factors. Creating an ideal environment involves isolating work areas, using HEPA filters, and implementing a thorough cleaning process with specialized tools and solutions. A controlled setting ensures precise control over cleaning methods, slows oxidation, and maintains vehicle aesthetics, preserving value over time in auto body shops.

Chrome repair restoration is an art that demands a meticulous approach, and the cornerstone of this process lies in creating a clean, controlled environment. The sensitivity of chrome surfaces requires a deep understanding of their care, especially during restoration. This article explores why maintaining a sterile workspace is vital for achieving top-quality results. We’ll guide you through controlling the environment step by step, ensuring that every aspect contributes to the longevity and beauty of restored chrome.

- The Sensitivity of Chrome: Unveiling the Need for Cleanliness

- Controlling the Restoration Environment: A Step-by-Step Guide

- Benefits of a Controlled Setting: Ensuring Quality and Longevity in Chrome Repair

The Sensitivity of Chrome: Unveiling the Need for Cleanliness

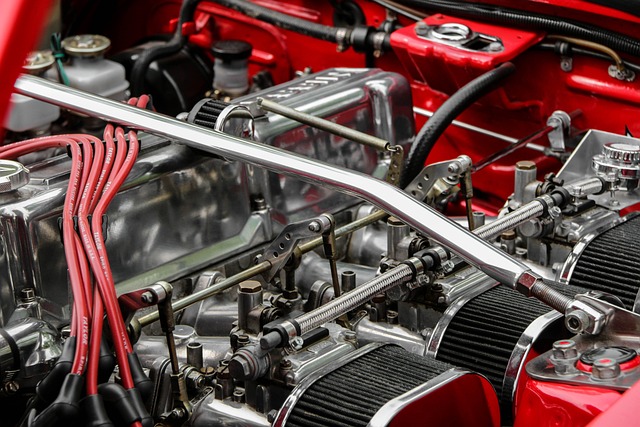

Chrome, with its gleaming and polished finish, is not just a decorative element on vehicles; it’s a delicate material that requires meticulous care during repair and restoration processes. The sensitivity of chrome lies in its susceptibility to scratches, stains, and corrosion, which can occur even from minor contact or exposure to certain substances. This vulnerability underscores the need for a clean and controlled environment during chrome repair restoration.

Maintaining sterility and minimizing external factors are crucial steps in preserving the integrity of chrome. In a collision center or vehicle restoration facility, ensuring proper ventilation, controlling temperature levels, and using designated cleaning solutions can prevent damage to the chrome’s surface. This meticulous approach not only enhances the quality of the repair but also ensures that the restored vehicle retains its original allure, making it a standout piece in any lineup, be it on the road or in a showroom.

Controlling the Restoration Environment: A Step-by-Step Guide

Creating a clean, controlled environment is paramount for successful chrome repair restoration. The first step is to isolate the work area from external contaminants. This involves using protective barriers like tarp and plastic sheeting to cover surrounding surfaces and floor areas. Next, invest in high-quality HEPA filters for your workshop or garage to trap fine particles and ensure air cleanliness.

For meticulous control, establish a systematic cleaning process. Start by removing all debris and dust from the chrome piece using compressed air or soft brushes. Then, employ isopropyl alcohol or specialized chrome cleaner solutions to dissolve residue and grease. Follow this with a thorough rinse using deionized water to eliminate any chemical remnants. Finally, dry the surface gently using microfiber cloths, preparing it for the restoration process, whether that involves straightening, polishing, or painting – including services like vehicle collision repair, tire services, or car paint services as needed.

Benefits of a Controlled Setting: Ensuring Quality and Longevity in Chrome Repair

A controlled environment plays a pivotal role in achieving top-quality chrome repair restoration results. This specialized setting ensures that every aspect of the repair process is meticulously managed, from dust and debris control to temperature regulation. By minimizing external variables, technicians can guarantee consistent precision and attention to detail throughout the project.

This meticulous approach offers several advantages. Firstly, it allows for precise control over cleaning methods, preventing any potential damage caused by aggressive cleaners or inadequate removal of contaminants. Moreover, a clean environment slows down oxidation and corrosion rates, leading to longer-lasting, more durable chrome finishes. This is particularly important in the auto industry, where cars are exposed to various weather conditions and elements, making a controlled repair environment essential in a collision center or car body shop for maintaining optimal vehicle aesthetics and value over time.

Chrome repair restoration requires a meticulous approach, with cleanliness and controlled environments being paramount. By understanding the sensitivity of chrome and implementing step-by-step environmental controls, professionals can ensure high-quality, long-lasting repairs. This not only benefits customers by enhancing the appearance of their items but also ensures the safety and effectiveness of the restoration process. A clean, controlled environment is the key to achieving exceptional results in chrome repair.